Custom-made solutions for greater wellbeing

R82 has been producing aids for children and young people with special needs since 1982. For children, youngsters and adults who need more support than a standard product can give them, R82 has, for more than 20 years, been able to provide them with a custom-made solution or Turtle as they are known.

Our entire custom-built Turtle product range is designed to improve daily life by reducing discomfort and pressure points, while promoting better posture when seated.

A unique solution for every user

At R82, we understand that every user has special needs and specific requirements when it comes to custom solutions. That’s why each moulded unit is meticulously crafted to provide the best possible support and comfort. Our design process begins with a comprehensive assessment of the user, thus ensuring that every contour and surface of the final product is tailored for optimal fit and functionality.

Whether the seating unit is 3D-printed or milled from foam to precisely match the user’s body shape, we understand that every single body is unique. This level of customisation helps to eliminate discomfort, reduce pressure points and promote better posture when seated.

Additionally, R82 offers a wide range of accessories, including head supports, foot supports, arm supports, and more. All of which can be combined and fitted to our moulded Turtle units.

Custom-made solutions: The process behind the moulded seat

At R82 you are in safe hands

For many years our high qualified R82 specialists, have worked closely together with the moulded solution advisers.

1. Shaped to the body

2. Fine adjustments

3. Complete 3D scan

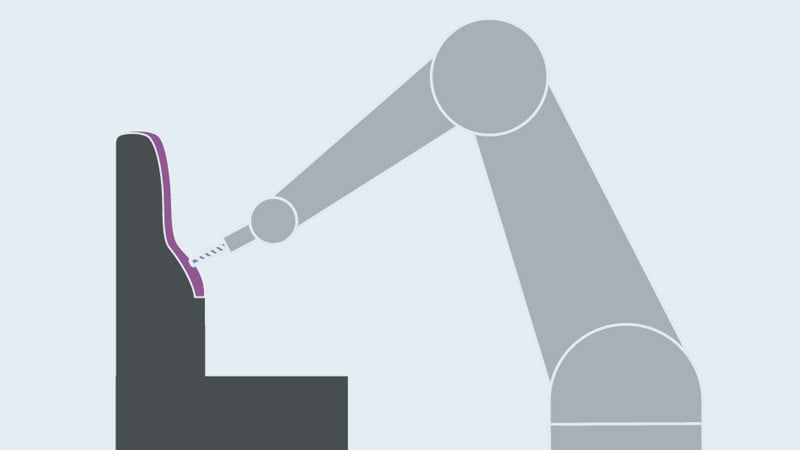

4. Robot precision

Utilising a highly accurate 3D scan of the contoured moulding bag, a quality-controlled turtle cushion is created by either 3D printing or precision foam milling. The cushion is meticulously crafted to replicate the user’s exact anatomical shape, through the accurate placement of reinforcements, inserts and other integrated components.

5. Final adjustments

As the final step before the cushions are integrated into the finished Turtle unit, each one undergoes a thorough inspection. The foam cushions are carefully refined to ensure a smooth surface, while the 3D-printed components are meticulously checked for any filament residue or manufacturing defects. From there, the cushions are ready for the final assembly into the Turtle unit.

6. Accessories and final mould

Our skilled Turtle division team installs the foam or 3D-printed cushions into the custom-made Turtle shell unit, which is then mounted onto an R82 frame or a frame from the approved combination list. Additionally, most of our standard accessories from our product range can be fitted to the Turtle unit, with customised accessories available upon request. The completed unit is then prepared for delivery.